High-strength steel repair offers superior solutions for demanding applications, particularly in automotive manufacturing and construction. This advanced process combines inspection, precision techniques like cold forming or welding with robotic arms, and damage restoration to enhance structural integrity without weakening the material. Beneficial for auto body painting and bumper repair, regular maintenance including inspections, coatings, tire pressure, and oil changes by skilled technicians extends the lifespan of high-strength steel components.

“Unleashing the Power of High-Strength Steel Repair Services: A Comprehensive Guide. High-strength steel (HSS) offers exceptional durability and strength, making it a preferred choice in various industries. This article delves into the intricacies of HSS repair services, exploring the unique properties that set them apart. We’ll navigate the repair process, from advanced techniques to cutting-edge technologies, ensuring optimal outcomes. Furthermore, we provide insights into long-term maintenance, helping you maximize the longevity of your HSS structures.”

- Understanding High-Strength Steel: Properties and Benefits

- The Repair Process: Techniques and Technologies Employed

- Expected Outcomes and Long-Term Maintenance Tips

Understanding High-Strength Steel: Properties and Benefits

High-strength steel is a specialized material engineered to offer exceptional strength and durability, making it an ideal choice for demanding applications. This type of steel possesses superior mechanical properties compared to conventional steels, allowing it to withstand extreme forces without failure. Its unique characteristics include elevated yield strengths, improved ductility, and enhanced toughness, enabling it to maintain structural integrity under severe conditions. These properties are achieved through advanced manufacturing processes and precise control over alloy compositions.

In the context of repair services, high-strength steel presents numerous advantages. When repairing structures or components made from this material, auto repair specialists can offer long-lasting solutions that match or exceed the original strength. This is particularly beneficial in industries where structural integrity is paramount, such as automotive manufacturing and construction. Unlike traditional steel repair methods, high-strength steel repairs provide superior resistance to corrosion and fatigue, ensuring longevity and performance. Moreover, its versatility allows for effective use in various applications, including auto body painting and car scratch repair, where restoring the structural soundness of vehicles is essential.

The Repair Process: Techniques and Technologies Employed

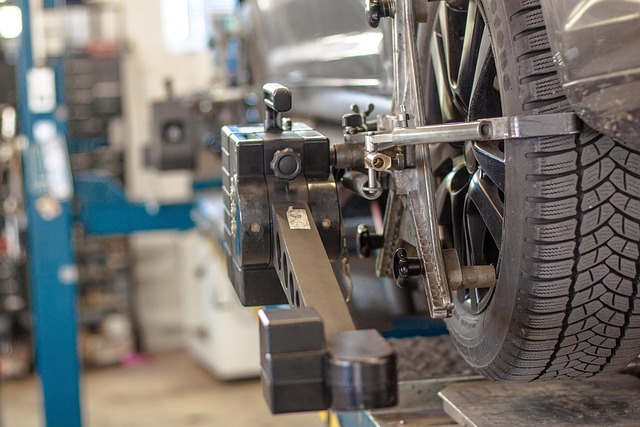

The high-strength steel repair process involves a combination of advanced techniques and technologies designed to restore structural integrity without compromising material strength. Professionals begin by thoroughly inspecting the damaged area, utilizing specialized tools to assess the extent of the issue. Depending on the severity, various repair methods are employed. For smaller dents or dings, techniques like cold forming or hammering can realign the metal without affecting its strength.

In cases of more significant damage, such as cracked or bent panels, a broader approach is taken. This might include cutting out affected sections and replacing them with new high-strength steel pieces, ensuring precise fitting for seamless integration. Advanced welding techniques, often facilitated by robotic arms, are utilized to fuse the repaired areas, maintaining the metal’s strength and durability. These processes are particularly crucial in auto bodywork and bumper repair services, where vehicle safety and aesthetics demand precision and strength.

Expected Outcomes and Long-Term Maintenance Tips

When it comes to high-strength steel repair, the expected outcomes are significant enhancements in structural integrity and overall vehicle performance. Skilled technicians use advanced techniques and specialized tools to meticulously fix damaged or corroded areas, ensuring the strength and stability of the metal. This process not only restores the car’s safety features but also extends its lifespan, making it a reliable and efficient mode of transportation.

For long-term maintenance, regular inspections are key. Auto bodywork experts recommend periodic checks for any signs of wear or tear, especially in areas prone to corrosion. Car repair services often suggest preventive measures like applying protective coatings, using quality waxes, and keeping the vehicle clean to deter rust. Additionally, maintaining proper tire pressure and ensuring timely oil changes can significantly contribute to preserving the integrity of high-strength steel components in both auto bodywork and car repair services.

High-strength steel repair services offer a robust solution for restoring structural integrity, leveraging advanced techniques to effectively fix and strengthen damaged components. By understanding the unique properties of high-strength steel and employing cutting-edge technologies, professionals can achieve exceptional outcomes that ensure longevity and enhanced safety. Regular maintenance guided by expert advice is key to maximizing the benefits of these repairs, making high-strength steel a preferred choice for demanding applications.